ISA Safety System: safe at work thanks to technology

The umbrian company ISA SpA – one the world’s most important manufacturers of commercial equipment for bars, ice-cream parlors, pastry shops as well as refrigerated display systems for the Food & Beverage and Retail industry – has put in place a series of safety reinforcing actions thus implementing, among the first in Italy, a high-tech “SWAT system – System Workers Advance Tracing” to guarantee the highest safety standards for all employees.

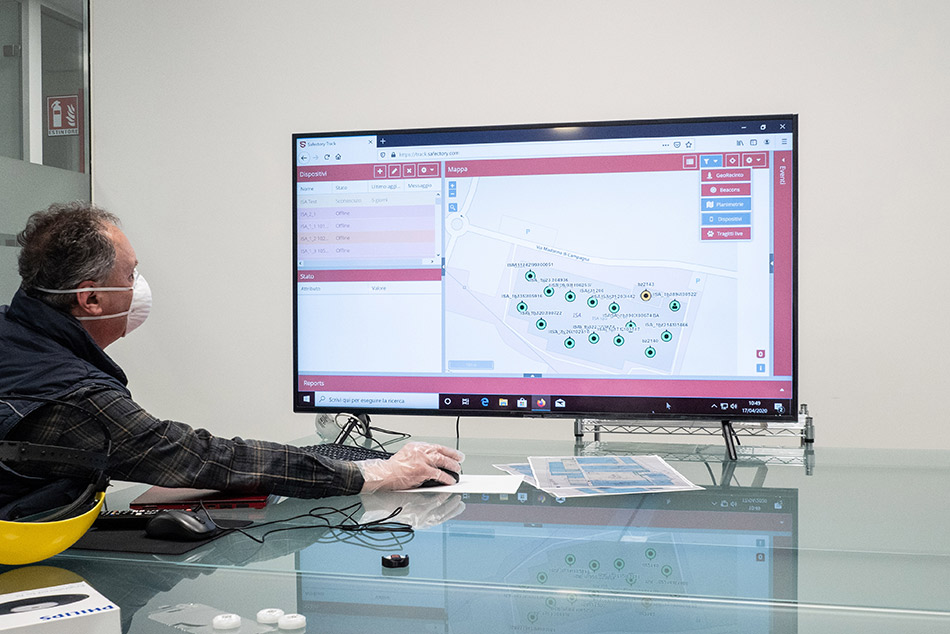

In order to train workers to respect each other’s safety distance, a high-tech project called “ISA SAFETY SYSTEM” was developed by ISA’s IT department in collaboration with HPE – Hewlett Packard Enterprise, world leader for high-tech solutions.

TAG tracing device

The central tracing system

Each operator will be equipped with a TAG (a device with the size of a small key ring) capable of performing two very important functions:

- Report to individual workers – by means of push notifications via APP on their smartphones – the contacts with individual colleagues under the distance of 1.5 meters for more than 15 seconds, in order to increase both their security and awareness.

- Allow the company to overlook all interactions between workers during their working activity, so as to promptly trace, in case of need and with utmost respect for privacy, all the contacts made by the worker concerned.

IISA Safety app available for workers

ISA Safety app available for workers

ISA Safety System adds to the other actions already put in place by ISA and agreed with the trade union organizations, aimed at bringing workers’ safety to the highest level.

Increase of individual protections.

In addition to ISA Safety System, each worker is equipped with a transparent front visor, Surgical or FFP2 masks, latex gloves (to be used underneat working gloves).

ISA safety devices

New security procedure for workers’ and suppliers’ access to the factory.

Body temperature measurement (mandatory for access to the factory). Creation of routes, using horizontal signage, to manage employee access and incoming and outgoing logistics in maximum safety.

ISA safety devices

Implementation of new security measures within the factory.

Creation of new routes for the transit and stationing of people; installation of additional protections between workstations including supply of products for sanitizing hands and workstations. Furthermore, meeting points have been closed (changing rooms, dining and break areas): bathrooms sanitation frequency has been intesified; in addition, a limited quota access through a traffic light system has been introduced.

Products for sanitizing hands and workstations

Limited quota access through a traffic light system

TV News: TGR Umbria, Channel Rai 3, 21 April 2020